We’re here to provide you with more information or help answer any questions you might have. Send us a note and we’ll get back to you as soon as possible.

MASS BALANCE

EXPLAINED

The push and market pull for change

The need for robust climate action, including reducing emissions and increasing resource efficiency, alongside opportunities to shift toward more sustainable solutions, are all core drivers to building a more sustainable future.

Over the 20th century, global chemical suppliers have heavily relied on fossil fuels to power facility sites, enhance chemical processes, build product portfolios, and transport and distribution logistics. Diversification and the modification of feedstocks is now widely seen as part of the solution when talking about the overall move away from fossil fuels within the industry. In combination with this push from within the industry the demand (pull) for recycled materials from downstream customers has also grown.

A recent Smartest Energy report showed that 81% of consumers are likelier to choose a brand that is taking positive actions towards a more sustainable world. Despite this, 45% of consumers are unaware of practices brands have adopted to encourage environmental sustainability; therefore, there is a gap in executing eco-friendly practices and communicating transparently throughout the chemical supply chain.

The Challenge

The chemical industry uses a small set of raw materials (or feedstocks) to produce tens of thousands of products. Traditionally this feedstock has been derived from fossil-based material.

When recycled feedstocks enter the same manufacturing system as fossil-based feedstocks, they cannot exist in physically divided flows. Separating and delivering these two different feedstocks at scale is often associated with operational and economic feasibility challenges.

The Industry Adoption of Mass Balance

In a bid to fill this gap, the mass balance approach has prevailed within the chemical industry, with growing emphasis over the last few years. At present, bio-based chemistry cannot serve as a viable solution for swiftly transitioning to renewable feedstocks on a large scale due to inherent constraints.

These constraints encompass factors such as product feedstock availability, infrastructure, research and development limitations, as well as cost considerations. Nevertheless, it does represent a significant step towards establishing a circular economy.

The Industry Adoption of Mass Balance

In a bid to fill this gap, the mass balance approach has prevailed within the chemical industry, with growing emphasis over the last few years. At present, bio-based chemistry cannot serve as a viable solution for swiftly transitioning to renewable feedstocks on a large scale due to inherent constraints.

These constraints encompass factors such as product feedstock availability, infrastructure, research and development limitations, as well as cost considerations. Nevertheless, it does represent a significant step towards establishing a circular economy.

How does it work?

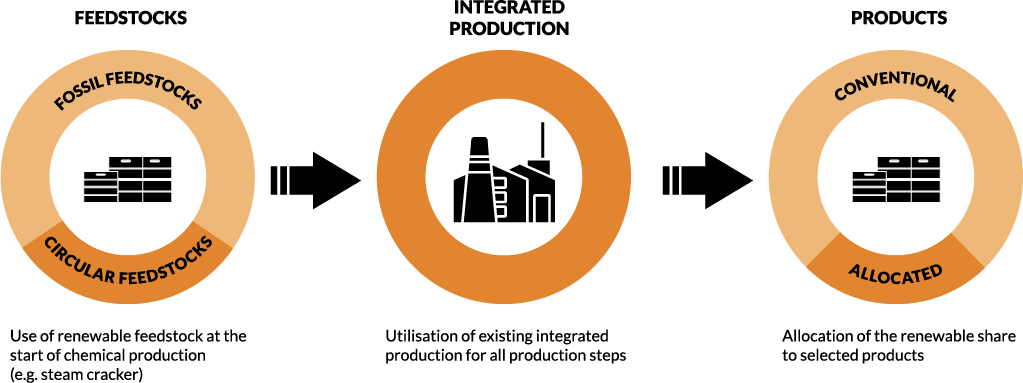

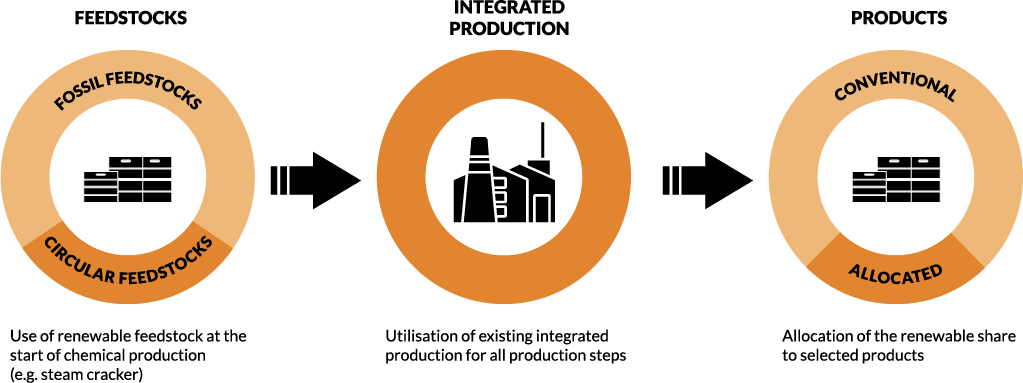

Mass balancing is a chain of custody in which certified and non-certified materials are mixed physically, but kept separate on a bookkeeping basis. This method documents and tracks circular, bio-circular and biological materials through complex manufacturing systems.

By using mass balance, companies can track how much circular, bio-circular and biomaterial has been used in their manufacturing systems and ensure that it corresponds precisely to the amount of certified content in the end products

Mass balance is a gradual step for manufacturers to substitute a percentage of a product's fossil fuel (non-renewable) content with circular sources. The primary fossil feedstocks in the chemical industry are naphtha and natural gas, which are further processed by cracking or part oxidation at elevated temperatures. In products, these feedstocks are replaced by bio-feedstocks, i.e., bio-naphtha and biogas (bio-methane) as well as recovered and recycled traditional feedstocks.. This method achieves an identical product quality and performance to which they are accustomed to and benefit from a sustainable drop-in solution, making a conscious contribution to environmental protection and limiting the climate crisis.

Feedstocks

Use of renewable feedstock at the start of chemical production(e.g. steam cracker)

Integrated Production

Utilisation of existing integrated production for all production steps

Products

Allocation of the renewable share to selected products

Key benefits of Mass Balance

- Easy accountability

- Gives formulators a sustainable 'drop-in' solution

- Significant reduction of carbon footprint/greenhouse gases

- The same product quality/efficacy is attained

- No need to adapt formulations, plants, or processes

- It can be implemented directly

- Certified according to well-accepted standards like REDcert2

- Removes the need for separate processing units & their potential environmental impact

- Enhances sustainability value proposition of products from source

- Early adoption encourages a gradual increase of renewable feedstock supply

Key Benefits of Mass Balance

Easy Accountability

Gives formulators a sustainable 'drop-in' solution

Significant reduction of carbon footprint/ greenhouse gases

The same product quality/efficacy is retained

No need to adapt formulations, plants or processes

It can be implemented directly

Certified according to well-accepted standards like REDcert2

Removes the need for separate processing units & their potential environmental impact

Enhances sustainability value proposition of products from source

Early adoption encourages a gradual increase of renewable feedstock supply

Key benefits of Mass Balance

- Easy accountability

- Gives formulators a sustainable 'drop-in' solution

- Significant reduction of carbon footprint/greenhouse gases

- The same product quality/efficacy is attained

- No need to adapt formulations, plants, or processes

- It can be implemented directly

- Certified according to well-accepted standards like REDcert2

- Removes the need for separate processing units & their potential environmental impact

- Enhances sustainability value proposition of products from source

- Early adoption encourages a gradual increase of renewable feedstock supply

Conclusion

The Mass Balance approach is an innovative yet simple method, allowing the evaluation of life cycle environmental impacts of bio-based and circular products without creating whole value chains separately from the fossil-based routes.s produits biosourcés et circulaires sans créer des chaînes de valeur entières distinctes des filières fossiles.

More on Sustainable & Circular

Transition to Circular

Discover how Univar Solutions can help you navigate the journey towards a Circular Economy, displacing fossil fuels with a mass balance approach.

More on Sustainable & Circular

Transition to Circular

Discover how Univar Solutions can help you navigate the journey towards a Circular Economy, displacing fossil fuels with a mass balance approach.

THE ISCC

ISCC strives for a world where biomass and other raw materials are produced in an environmentally, socially, and economically sustainable manner.

Useful Links & Sources

- https://www.iscc-system.org/about/circular-economy/mass-balance-approach/

- PlasticsEurope position paper on the "Mass balance approach to accelerate the use of renewable feedstocks in chemical processes" (29 January 2020)

- https://www.epa.gov/ghgemissions/global-greenhouse-gas-emissions-data#:~:text=Since

- https://www.basf.com/global/en/who-we-are/sustainability/we-drive-sustainable-solutions/circular-economy/mass-balance-approach/biomass-balance.html

- https://www.recyclinglives.com/news/general/report-reveals-81-people-prefer-buy-sustainable-sellers

- Study "A methodology for integrating the biomass balance approach into life cycle assessment with an application in the chemicals sector" by Adisa Azapagic et al. in "Science of the total environment" (2019)

- Mass balance approach for the sustainable chemicals transition

As a global leader in chemical and ingredient distribution, we take our Environment, Social, and Governance (ESG) responsibilities seriously, and:

![]()

Employ environmentally conscious protocols and technologies

![]()

Encourage community engagement

![]()

Establish practices and partnerships with integrity

More on Sustainable & Circular

Link to ISCC Acreditation page

cras fermentum odio eu feugiat pretium nibh ipsum consequat nisl vel pretium lectus quam id leo in vitae turpis massa sed elementum tempus egestas sed sed s

Sustainable Solutions

Discover how we can help customers develop and market sustainable products

2025 Goals

2025 Goals

In an effort to drive meaningful change and show our continuous commitment, we've outlined a new set of ESG sustainability goals.

These ambitious standards will allow us to better serve our customers, employees, and partners today, so that together, we can shape a better tomorrow.

Climate Action

Implement technology, processes, and culture to support our sustainability journey.

Reach 20% absolute reduction in CO2e emissions by 2025, and 40% by 2030

Achieve net-zero direct emissions by 2050

Safety

Keep our employees, vendors, and customers safe at work

By 2025, reduce TCIR by 20%

Achieve 100% alignment by and utilization on our global safety program by 2025

Resource Use

Embed the principles of circularity and operational excellence.

Reduce hazardous waste and water waste by 15% by 2025

Triple non-hazardous waste recycling rates by 2025

Introduce sustainble water use at all high-risk sites

Release Prevention

Support the responsible handling of materials across our operations and supply chain.

Reduce significant chemical releases by 40% by 2025

Sustainable Sourcing

Drive improved sustainability performance and minimum standards across our diverse supplier base.

By 2023, get 100% of active suppliers to agree to our Code of Conduct

Assess 80% of suppliers on their sustainability performance (by spend) by 2025

Diversity, Equity & Inclusion

Increase representation across the organization and encourage employees to lead with their authentic selves.

Maintain a 100% score on the Corporate Equality Index, and at least a 78% score on the Employee Engagement Diversity & Inclusion Index

Increase female representation and ethnic diversity at the people leader level (and above) by 2025

Sustainable Solutions

Leverage sustainable products, services, and practices.

Develop sustainable characteristics for all products

Communicate the key sustainability impacts for non-product-related services

Offer circular packaging solutions for all suitable products

Community Engagement

Demonstrate our committment to local communities

Make charitable contributions through the Univar Solutions Foundation (or other similar means)

Establish employee volunteer hour contributions, and company matching gift contributions

Climate Action

Implement technology, processes, and culture to support our sustainability journey.

Reach 20% absolute reduction in CO2e emissions by 2025, and 40% by 2030

Achieve net-zero direct emissions by 2050

Safety

Keep our employees, vendors, and customers safe at work

By 2025, reduce TCIR by 20%

Achieve 100% alignment by and utilization on our global safety program by 2025

Resource Use

Embed the principles of circularity and operational excellence.

Reduce hazardous waste and water waste by 15% by 2025

Triple non-hazardous waste recycling rates by 2025

Release Prevention

Support the responsible handling of materials across our operations and supply chain.

Reduce significant chemical releases by 40% by 2025

Sustainable Sourcing

Drive improved sustainability performance and minimum standards across our diverse supplier base.

By 2023, get 100% of active suppliers to agree to our Code of Conduct

Assess 80% of suppliers on their sustainability performance (by spend) by 2025

Diversity, Equity & Inclusion

Increase representation across the organization and encourage employees to lead with their authentic selves.

Maintain a 100% score on the Corporate Equality Index, and at least a 78% score on the Employee Engagement Diversity & Inclusion Index

Increase female representation and ethnic diversity at the people leader level (and above) by 2025

Resources & Reporting

Explore helpful ESG reporting, performance, and policy resources