We’re here to provide you with more information or help answer any questions you might have. Send us a note and we’ll get back to you as soon as possible.

As a global leader in ingredient distribution, we deliver enzymatic solutions from Novozymes, a world leader in innovative and sustainable biotechnology. Novozymes’ product portfolio contains an extensive range of cutting-edge enzymes and related technologies that serve many beverage production applications while benefiting local farmers and helping to reduce cost and waste for better beverage processes. Discover how we are supporting innovation through enzyme distribution for beverage manufacturers.

Enhance your brew with nature's formula

Natural catalysts that speed up critical steps in the brewing process, enzymes have been a part of brewing for thousands of years. Today, innovative brewers are using enzymes to develop their business beyond traditional beer boundaries. With enzymes, brewers can create new tastes and claims, maintain consistent production and develop premium offerings to meet new consumer expectations.

Enzyme benefits for brewers quality and stability

Rethink traditional brewing. Improve the quality of your yield.

Enzymes have been a natural part of brewing for thousands of years. Today’s brewers are using enzymes to experiment with new tastes and meet claims for wellness and environmentally conscious consumers. As a beverage solution, enzymes help beverage producers achieve consistently high beer quality and improve sustainability through cost reduction and optimized production processes.

Introducing Lumista® Gold: A ground breaking solution for sustainable beer production

Lumista Gold effectively minimizes haze-active proteins in beer, enhancing its colloidal stability without altering any other characteristics. This proline-specific endopeptidase targets proteins rich in proline residues, preventing the formation of large haze-active structures. This results in a remarkable reduction of visible haze, ensuring a clear and stable beer throughout its shelf life.

- Colloidal Stability:

Maintains consistent appearance and quality throughout beer shelf life - Production Efficiency:

Optimizes tank utilization, boosting capacity and flexibility - Energy Savings:

Reduces energy consumption by streamlining beer stabilization - Cost-Effective:

Lowers cost-in-use compared to other solutions - Ease of Handling:

Safe and easy application with minimal volume, no powder handling - Gluten Reduction:

Meets gluten regulations for barley/wheat malt-based beers - Reliability and Sustainability:

Ensures uninterrupted production, quality, and timely delivery

At-a-glance: Enzyme Benefits for Brewing

Focus Area

Improve total production capacity and efficiency

Novozyme Concepts

- Faster throughput and increased extract

- Faster maturation and fermentation

- Cost-efficient cereal cooking

Brewery Benefits

- Ensured process predictability - More brews/week

- Increased brewery efficiency and productivity

- Reduced maturation time

- Optimal starch extraction and shorter mashing time

Cost reduction and/or cost leadership

-

Raw material cost savings

-

Faster maturation and fermentation

-

Cost-efficient cereal cooking

- Reliable process using any malt and adjuncts

- Lowest raw material costs through maximal use of adjunct - Simple and reliable process using adjuncts

- Reduced fixed costs

Ensure consistent beer quality

- Faster throughput and increased extract

- Raw material cost savings

- Faster maturation and fermentation

- Improved attenuation control

- Ensure predictable malt behavior

- Ensure consistent processes and yields

- Elimination of diacetyl off-flavors

- Ability to achieve a specific attenuation goal

Keep pace with consumer trends

- Improved attenuation control

-

Extend product branding to "low-carbohydrate" beers

-

Extend product branding to "light" beers

-

Production of special beers

At-a-glance: Enzyme Solutions for Brewing

Cost-effective Cereal Cooking

Recommended Products

Termamyl® SC 4X

Termamyl® SC DS

Termamyl® SC BrewQ

Termamyl® Classic

Benefits

- Faster and more consistent liquefaction

- Lower mash viscosity, resulting in easier wort production

- No risk of resistant or retrograded starch formations, or insufficient saccharification

- Reduced processing costs through more efficient liquefaction

- Improved flexibility in the use of various cereal grain adjuncts

- Reduced energy consumption due to lower temperatures when handling decoction mashes

Main Enzyme Activities

α-amylase

Efficient Wort Separation and Beer Filtration

Recommended Products

Ultraflow® MAX

Ultraflow® XL

Termamyl® SC BrewQ

Ultraflow® Core

Benefits

- Minimal fluctuation in the brewing process

- Consistently fast wort separation

- Higher brewhouse yield and efficiency

- Longer filtration cycles and lower filtration costs

- Allows brewing at higher gravity

Main Enzyme Activities

β-glucanase

Cellulase

Xylanase

Attenuation Control and Light Beer Production

Recommended Products

Attenuzyme® Pro

Attenuzyme® Core

Attenuzyme® Clip

Ultraflow® Core

Benefits

- Consistent attenuation control regardless of raw material

variability or process fluctuation - Produces wort that enables highly attenuated beers

- Potential for shorter mashing times and lower

enzyme dosage

Main Enzyme Activities

Glucoamylase

Pullulanase

α-amylase

Raw Material Optimization

Recommended Products

Attenuzyme® Pro

Attenuzyme® Core

Attenuzyme® Clip

Ultraflow® Core

Benefits

- Enables the use of adjuncts in different ratios and allows the sourcing of locally grown raw materials with varying qualities

Main Enzyme Activities

Selected combination of different enzymes

Fermentation Control with Fan Optimization

Recommended Products

Attenuzyme® Pro

Attenuzyme® Core

Attenuzyme® Clip

Ultraflow® Core

Benefits

- FAN control for consistent yeast growth and optimal fermentation

- FAN optimization in high barley/adjunct brewing

- Improvement of mash lautering/filtration

- Yield improvement

Main Enzyme Activities

Protease

Diacetyl Control

Recommended Products

Attenuzyme® Pro

Attenuzyme® Core

Attenuzyme® Clip

Ultraflow® Core

Benefits

- Consistently low levels of diacetyl in the final beer

- Shorter maturation time leading to higher capacity utilization

- Compensates for seasonal fluctuations in sales

- Lower energy consumption

- Leaner process conditions for low alcohol beers

Main Enzyme Activities

α-acetolactate -

decarboxylase

Membrane Cleaning

Recommended Products

Attenuzyme® Pro

Attenuzyme® Core

Attenuzyme® Clip

Ultraflow® Core

Benefits

- Reduced operational costs

- Increased lifespan of membrane cartridges

- Regeneration step easily integrated into

- CIP automation programs

Main Enzyme Activities

β-glucanase

Cellulase

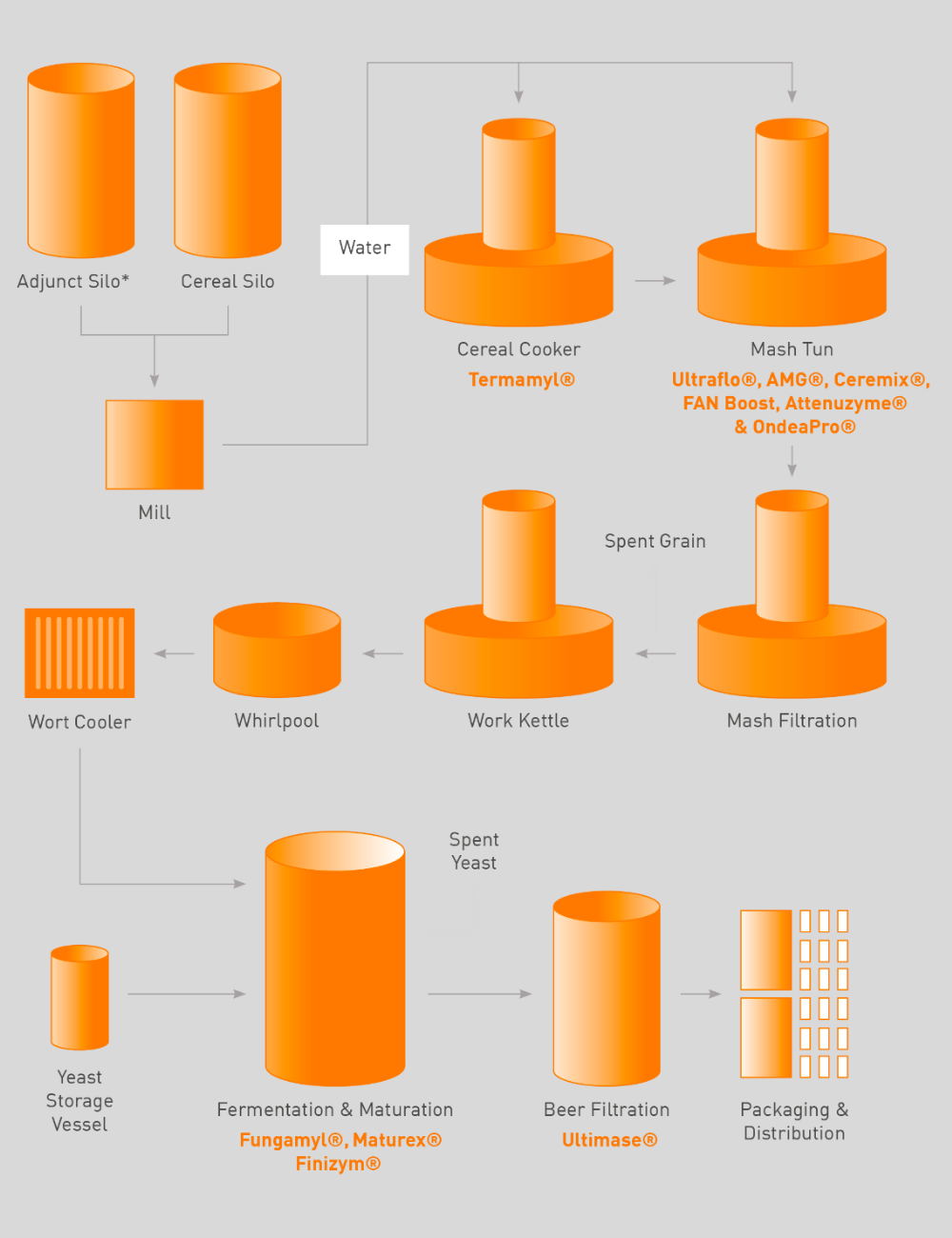

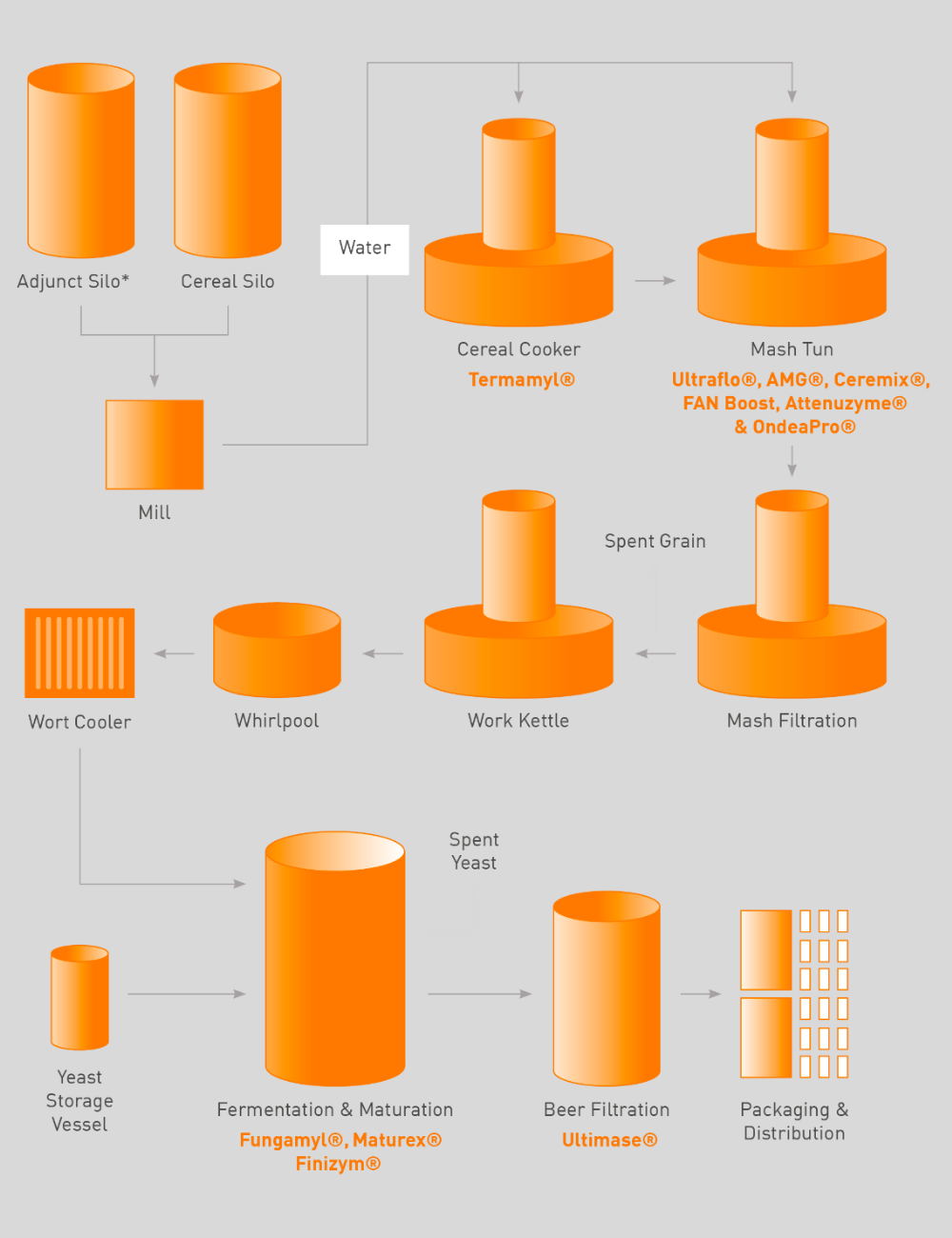

Brewing Process